Since inception, we have believed in advanced technology as an enabler that makes us better and faster. We developed the first software for simulating drive systems and the original data acquisition systems for taking dynamic measurements on live engines. That approach has continued to evolve.

Doing it our way

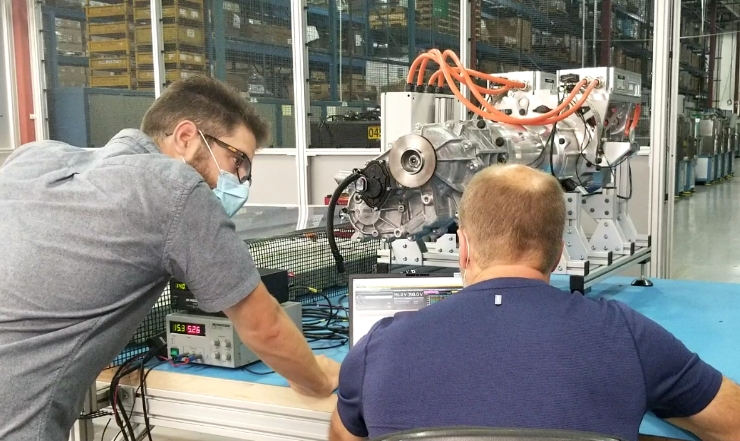

Not only do we build solutions for our customers, but we do it for ourselves, too. We design, build, and maintain all our own very sophisticated production equipment including robotics, controls, inspection, assembly, and more. Similarly, we design and build testing machines that can stress automotive parts well beyond what vehicles can do, whether that is force, acceleration, temperature, frequency or whatever is necessary. We do all of this in the name of complete quality control, which is evident in the confidence and trust customers place in us.

Project Discipline

Taking ideas from napkin sketch to production is complex and, as with a start-up, requires significant investment and good management.

Concept

Everything starts with an idea from somewhere. We like to invest the time and effort to carefully explore the value proposition and how to validate it.

System proof of concept

At this stage, expertise, benchmarking, and discussing with the customer are all essential to support technical fundamental analysis such as modelling and 1D-3D simulation.

Prototype

Physical evaluations of the intended function and benefits utilizing representative hardware, software, and controls.

Testing

Test engineers build and use all types of electronic data acquisition and processing to evaluate whether physical prototypes behave as designed or expected. These tests may involve vehicles, simulators, component parts, dynamometers, to name a few.

Success

Our legacy is our satisfied clients and the success they share with Litens.